Ministry of Supply: Bringing 3D Printing and Innovative Materials to Office Wear

KEY POINTS

Ministry of Supply is a fashion tech firm that creates performance dress shirts by combining innovative materials with 3D printing.

- Ministry of Supply applies technology to fabrics to enhance the wearer’s experience by giving everyday office clothing features such as greater stretchability, moisture wicking and wrinkle resistance.

- The company’s garments are made-to-order by employing cutting-edge production techniques such as 3D printing.

- Ministry of Supply introduces fabrics with enhanced properties to the office wear segment, a relatively untapped market with great potential for the application of tech materials. Meanwhile, the advanced and tailored manufacturing process adopted by the company can help eliminate waste and overproduction.

Ministry of Supply: Applying Tech to Everyday Apparel

More and more big apparel brands such as Adidas are experimenting with 3D printing of their products. Meanwhile, a growing number of niche firms are bringing new fabric technologies to market. In this report, we look at one company that combines 3D printing of clothing with innovative fabric technologies.

Ministry of Supply is a fashion tech firm that brings new technology to fabrics to give everyday office clothing features such as greater stretchability, moisture wicking and wrinkle resistance, by using materials from fields such as aerospace. Ministry of Supply also uses an innovative made-to-order manufacturing process that employs cutting-edge production techniques such as 3D printing.

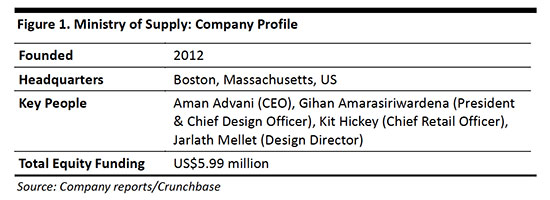

The company was founded in 2012 by three Massachusetts Institute of Technology (MIT) graduates, when Ministry of Supply launched its Apollo dress shirt. The launch was funded through a very successful crowdfunding campaign on funding platform Kickstarter, which raised a total of US$429,276 from 2,798 backers. Since then, the company has raised a total of US$5.99 million in equity funding, with the latest funding round of US$2.5 million in July 2016, according to Crunchbase

How Ministry of Supply Disrupts Apparel: Tech Materials and 3D Printing

Ministry of Supply’s business model disrupts the fashion sector in two ways: 1) by applying innovative materials to the production of everyday office clothing; and 2) by employing cutting-edge production techniques such as 3D printing to manufacture the garments.

1) Innovative materials: Ministry of Supply applies innovative materials from industries such as aerospace to apparel manufacturing, to create performance everyday office clothing. For the firm’s flagship product, the Apollo shirt, the company uses Phase Change Material—a material developed by NASA to insulate space suits—infused in a synthetic fiber. This combination creates a fabric that stretches and breathes 19 times better than regular cotton. The material allows the regulation of the body temperature, enabling the wearer to feel comfortable, fresh and clean throughout a long day at work. While the applications of fabrics with enhanced properties have been mainly focused on sportswear and activewear, Ministry of Supply brings this technology to a larger segment of the market in which the potential for the application of tech materials is relatively untapped.

2) Innovative manufacturing: Ministry of Supply’s garments are made-to-order by employing cutting-edge production techniques such as 3D printing. The 3D print-knit process used is completely seamless, as the printer programs the shape of the fabrics it needs to create the garment, with no need to cut and stitch. This results in more durable garments with no weak points which are more sensitive to tearing. This manufacturing process also eliminates: i) manufacturing waste, as all fabric used goes into the garment, given the absence of cutting and stitching; and ii) overproduction, as the item is made-to-order and produced only once as it is ordered by the customer.

Shoppers can customize their orders by choosing colors, cuffs, buttons and other personalized details. The garments can be ordered online or in-store. Ministry of Supply is positioned as a premium fashion brand. The Apollo shirt comes with a price tag of US$115, per the company’s website. This is broadly in line with aspirational brands such as Hugo Boss, whose shirts are priced from US$125 to US$225 on Nordstrom.com at the time of writing.

Brick-and-Mortar Stores Complement the Shopping Experience

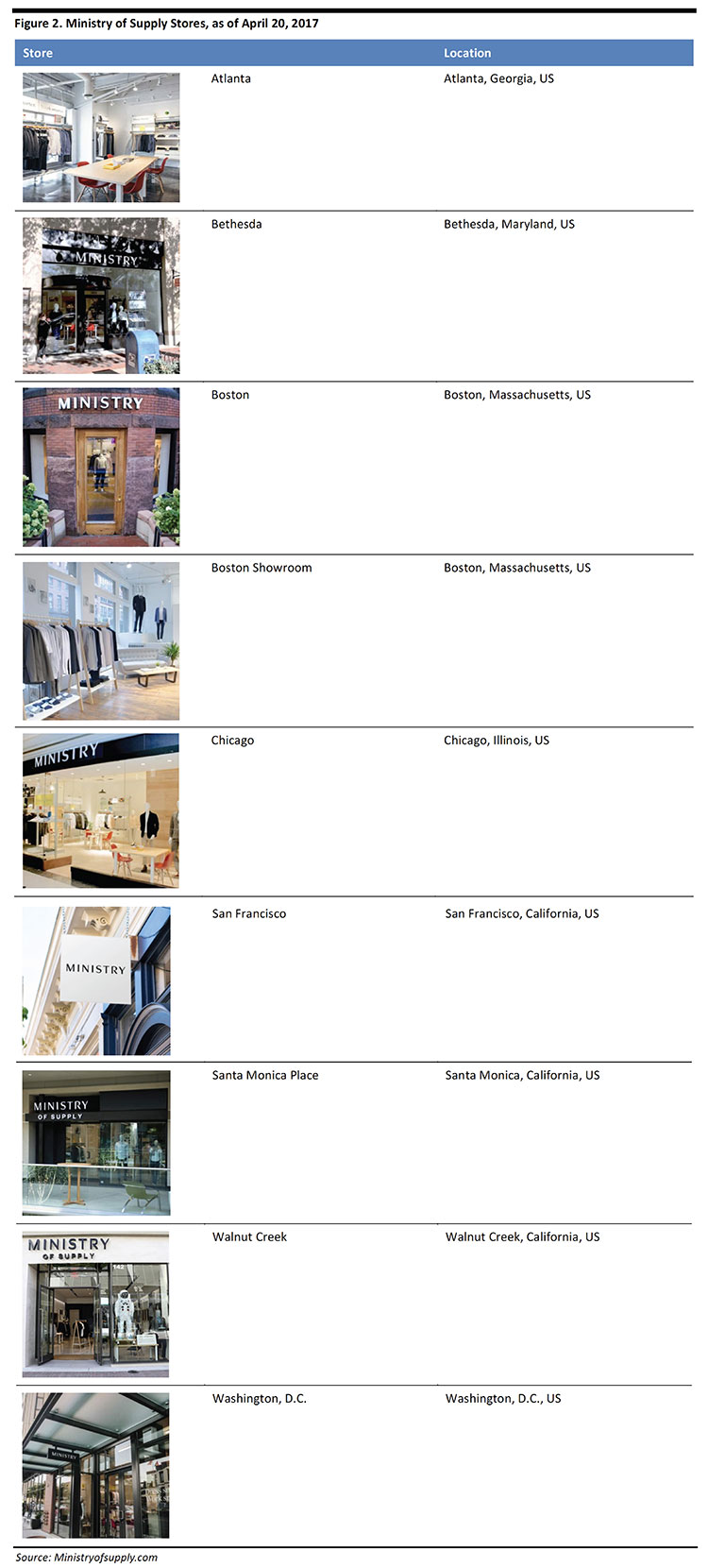

Although Ministry of Supply started as an Internet pure play, the company considers it important to have a physical store presence in key locations. This allows customers to complement the online experience by touching the product and understanding the quality and characteristics of the technologically advanced fabrics used in the production of the garments.

In the stores, shoppers can try on samples from the collection and can collect, return or exchange items purchased online or in-store. In-store, shoppers can also have their measurements taken prior to processing their order. The tailored garment will then be ready within three business days. Shoppers visiting the physical stores can also have some items 3D printed on the spot through in-store printers.

Ministry of Supply’s first brick-and-mortar store opened in Boston in 2014, and at the time of writing, the company had a network of nine stores located throughout the US.

Performance Tech Materials and 3D Printing in Apparel

Ministry of Supply introduces an innovative business model that combines made-to-order advanced manufacturing and tech materials to enhance everyday garments. But it is not alone in using 3D printing and tech materials; these technologies are gaining momentum in apparel as more companies experiment with them.

Sportswear and athleisure firms use 3D printing to create customized products and to react faster to changing fashion trends, while everyday office clothing manufacturers are starting to use tech materials to enhance the performance of their garments and the convenience for the wearers.

In the next section, we see how sportswear company Adidas and fashion tech company Induo are embracing 3D printing and tech materials.

Adidas Futurecraft 4D: Mass-Produced 3D Printed Sneakers

Adidas is the first large sportswear company to announce a plan to scale 3D printing in sneaker manufacturing. To this end, Adidas is collaborating with Silicon Valley tech company Carbon on the launch of Futurecraft 4D, a line of performance footwear, during the fall/winter season 2017. The announcement was made on April 7, 2017.

Carbon has developed a special 3D printing process, Digital Light Synthesis (DLS), which uses digital light projection, oxygen-permeable optics and programmable liquid resins to generate high-performance, durable polymeric products.

Adidas aims to sell 5,000 pairs of Futurecraft 4D shoes during the fall/winter season 2017 and to further scale production in the coming seasons. In 2015, the firm introduced Futurecraft 3D, a running shoe with a Primeknit upper and a lattice-work 3D-printed midsole which can be tailored to the cushioning needs of the wearer. However, Carbon’s DLS technology will enable Adidas to scale and mass produce Futurecraft 4D.

Other sportswear companies including Nike, Under Armour and New Balance have used 3D printing to make prototypes or special items for sponsored athletes, but so far, these companies have not used the process to produce for the mass market.

Induo: Applying Tech Textile to Everyday Clothing

Induo manufactures shirts made with tech fabrics. The firm, based in Paris, produces a coated fabric that repels oils and water and manufactures shirts made with the special textile.

Shirts produced by the company have water- and stain-resistant properties that enhance the performance of the garment and make it repellent and breathable to prevent stains from liquids and sweat.

The company was established in 2014 after developing the tech fabric used for its shirts in collaboration with top textile engineers at the Centre of European Textile Intelligence (CETI), a France-based textile research center where the company was incubated.

Readers can find our December 2016 profile of Induo at bit.ly/FungInduo.

Key Takeaways

Ministry of Supply is a fashion tech firm that creates performance dress shirts by employing cutting-edge production techniques and materials.

The company’s business model disrupts the fashion sector in two ways:

- By applying innovative materials to create performance everyday office clothing.

- By employing made-to-order cutting-edge manufacturing processes such as 3D printing.

Ministry of Supply brings fabrics with enhanced properties to a large segment of the apparel market, such as office wear, in which the potential for the application of the technology is relatively untapped. Meanwhile, the advanced and tailored manufacturing process adopted by the company can help eliminate manufacturing waste and overproduction.